Controlled cooling

Even

Custom

Hygienic

Frequently Asked Questions

Feel free to contact us.

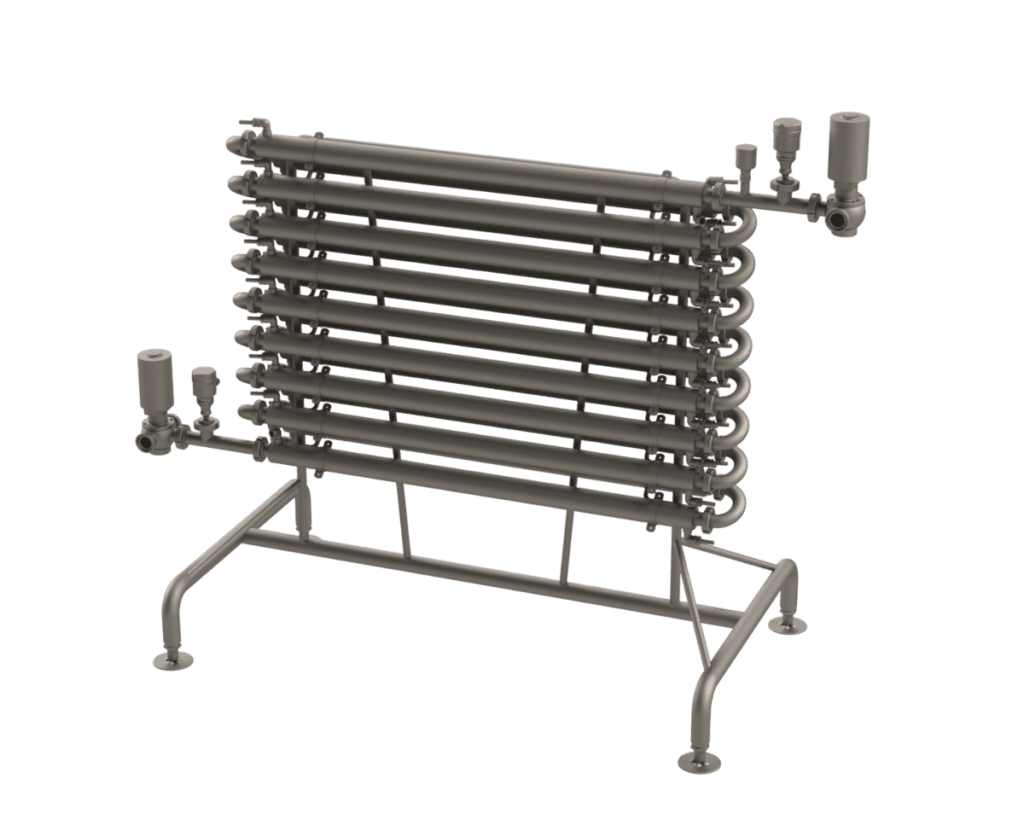

Flat surface cooling

The Vomatec Cooling Table is built to cool poured confectionery masses like caramel, nougat, fondant or toffee quickly and evenly. Its flat stainless-steel surface contains an internal water jacket, allowing chilled water to circulate and remove heat in a controlled and efficient way.

This method ensures consistent crystallization and product texture across the full surface, preventing uneven cooling or hotspots that could compromise product quality. The result is a smooth, stable mass — ready for shaping, forming, or further processing.

The Cooling Table is available in various lengths and widths and can be integrated into your production line or used as a stand-alone unit. Its robust and hygienic design supports fast cleaning, long-term durability, and compliance with food safety standards.

Other machines

The Vomatec Cooling Table is a flat, stainless-steel cooling surface designed for sugar-based confectionery masses such as caramel, nougat, toffee, and fondant. Ideal for batch cooling, this water-jacketed table ensures rapid and uniform temperature reduction after cooking or pouring.

Chilled water circulates through the internal jacket to cool the product evenly across the surface, promoting consistent crystallization and stable texture. This makes the Vomatec Cooling Table a key part of the cooling process in artisan and industrial candy production.

Manufacturers use this table for post-cooking cooling of poured candy slabs, sugar syrups, or soft caramel masses. It is available in custom dimensions to fit your workspace or line layout.

With hygienic stainless-steel construction and a smooth, easy-to-clean surface, the Vomatec Cooling Table meets the demands of modern confectionery environments. Whether you’re producing nougat, hard toffee, or traditional fondant, this industrial cooling solution helps improve product quality, reduce cooling time, and streamline production.