Precision heating for perfect results

Gentle

Accurate

Hygienic

Frequently Asked Questions

Feel free to contact us.

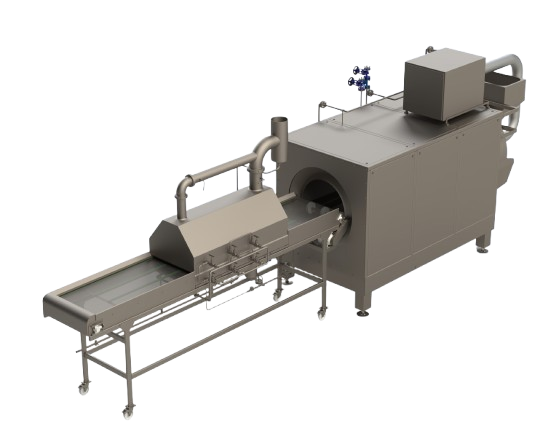

Consistent results in marshmallow

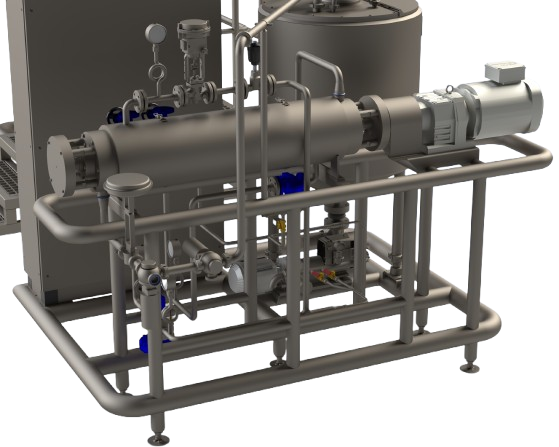

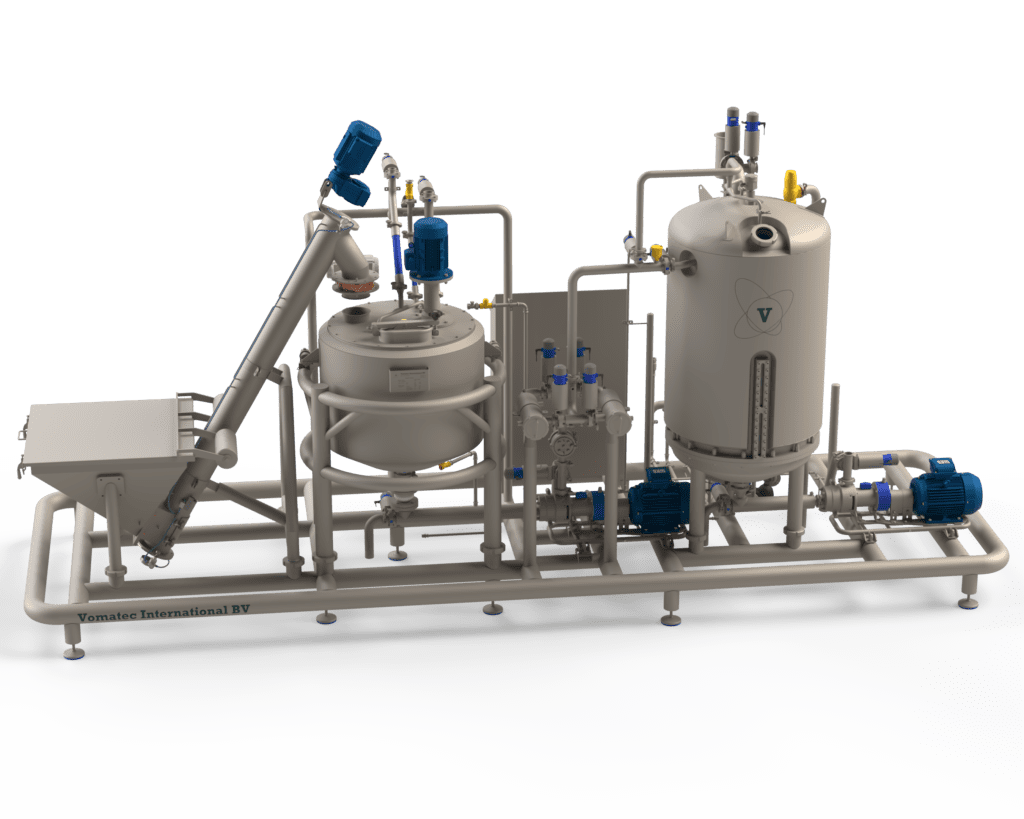

The VomaTHERM batch cooking system combines a dedicated premix vessel with a Thermosyphon Cooker to ensure controlled, repeatable processing of heat-sensitive confectionery masses. In the premix vessel, ingredients are blended into a uniform slurry before being gently circulated through the cooker. Thanks to natural thermosyphon movement, the product is evenly heated without mechanical agitation, reducing the risk of burning or buildup.

This process allows precise control over temperature and moisture, which is essential for achieving the light, elastic texture typical of high-quality marshmallow. The system is built for stability and hygiene, with a fully drainable cooking vessel, vacuum capability, and options for CIP integration. Whether used in pilot setups or larger-scale lines, the VomaTHERM offers reliable performance with minimal operator intervention.

Other machines

Thermosyphon batch cooker for heat-sensitive confectionery

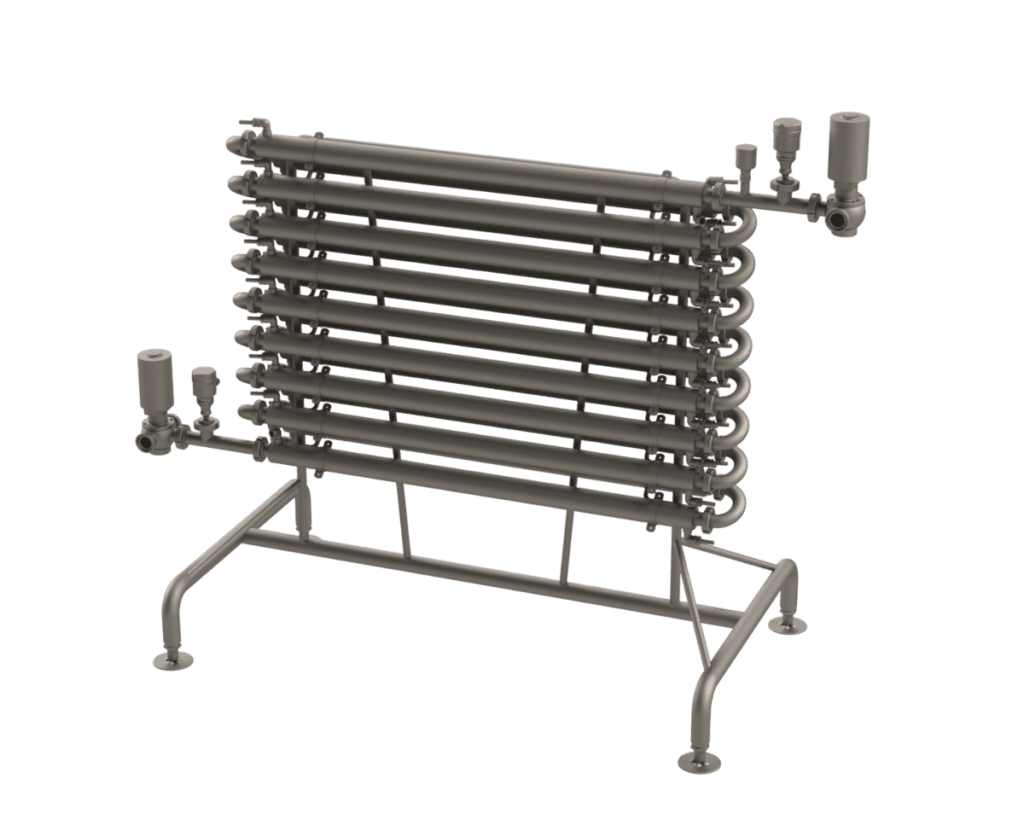

The VomaTHERM Thermosyphon Cooker is a batch cooking system developed for the controlled processing of heat-sensitive and viscous confectionery masses. Using natural thermosyphon circulation, it heats product evenly without mechanical stirring — reducing the risk of burning and preserving product structure.

The system is ideal for recipes such as marshmallow, caramel, chewy candy, and nougat, where precise temperature control and stable evaporation are essential. With an integrated vacuum system, the VomaTHERM supports efficient moisture removal and consistent texture.

Constructed in stainless steel and built for long-term operation, the VomaTHERM fits into both small and large-scale production setups. Its hygienic design is fully drainable and easy to clean, minimizing downtime and simplifying maintenance.

For confectionery manufacturers with small to mid-scale output, the VomaTHERM offers an energy-efficient, flexible solution. When production volumes increase, a continuous cooking system may be more suitable. In that case, the VomaDISS continuous cooker delivers higher throughput with precise, scalable control.