Premium polishing

No

Consistent

Fast cleaning

Frequently Asked Questions

Feel free to contact us.

Engineered for a clean finish

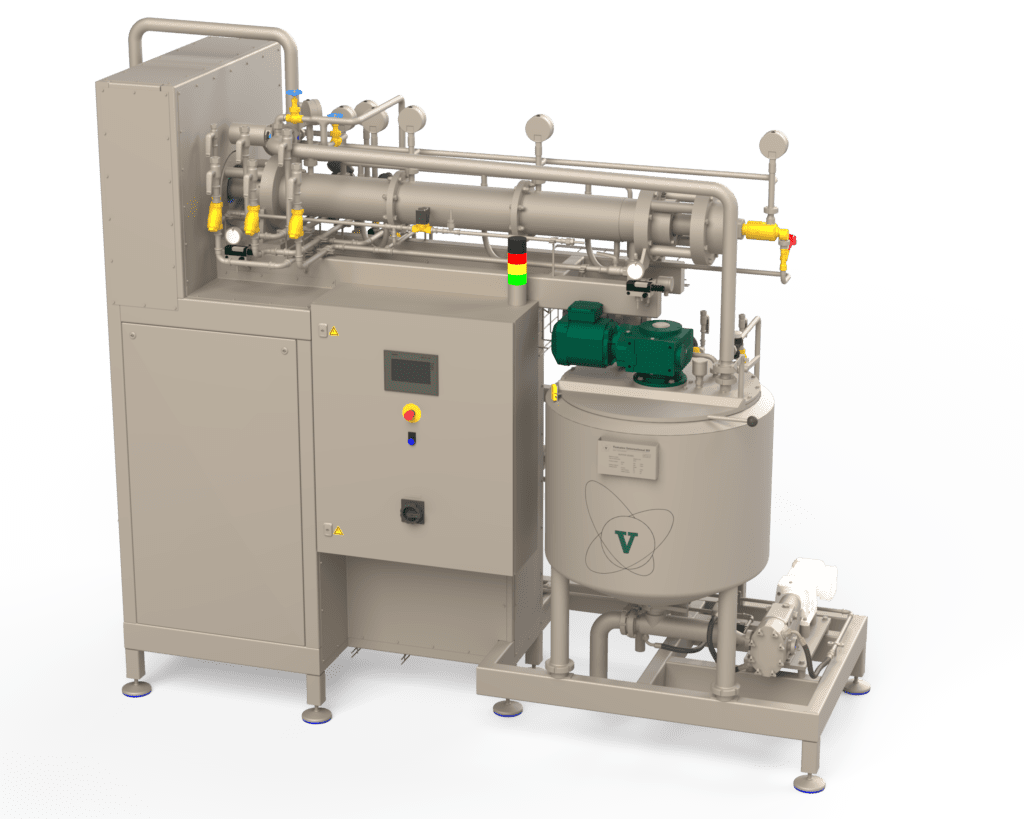

The VomaSHINE finishes molded jelly and gummy products with a clean, even coating. The stainless-steel drum is designed to guide the product gently while distributing oil or glaze uniformly across the surface. This process protects the shape and texture while enhancing visual appearance and reducing stickiness.

The drum design ensures a residence time of approximately 5 to 7 minutes, allowing the product to remain in motion long enough to achieve a consistent result. The system operates continuously and handles a wide variety of product formats without manual intervention.

Built entirely from high-grade stainless steel, the VomaSHINE meets strict hygienic standards and is easy to clean. Vomatec has deliberately chosen to build its polishing drums to the highest level of mechanical and hygienic quality available.

The system is available as a pilot unit or in full industrial capacities. Whether placed in a test environment or high-output production line, the VomaSHINE provides a reliable, clean finishing step for modern confectionery processes.

Other machines

he VomaSHINE is a continuous polishing and oil-coating machine for jelly and gummy confectionery. It uses a hygienic stainless-steel drum to gently move products while applying a uniform glaze or oil layer. This improves visual appearance, reduces sticking, and helps maintain freshness throughout the shelf life.

With a fixed residence time of 5 to 7 minutes, the VomaSHINE ensures consistent coating in a continuous process. The system is available for both pilot-scale and high-capacity production and integrates directly into new or existing confectionery lines.

Its easy-to-clean construction supports hygienic operation and fast product changeovers, reducing downtime. Whether you’re finishing starch-molded gummies, sugar-free jellies or functional soft candy, the VomaSHINE delivers reliable polishing performance with minimal product loss.

For manufacturers seeking a high-quality glazing system for jelly or gummy products, the VomaSHINE offers a durable, stainless-steel solution built for clean results and continuous production.