High-Performance Mixing

Lump-Free

Fast

Accurate

Frequently Asked Questions

Feel free to contact us.

Solving mixing challenges

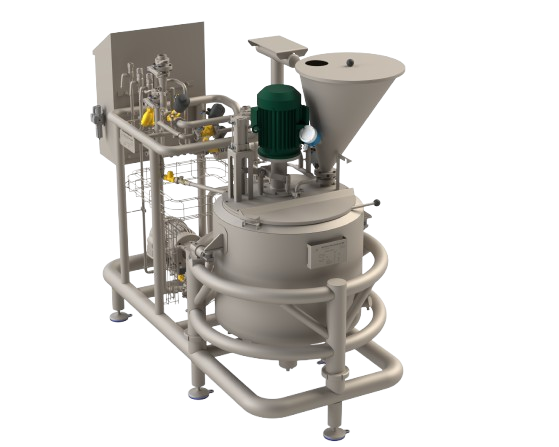

Struggling with clumping or inconsistent results when mixing powders like gelatin, pectin, or milk powder? The VomaBPS ensures smooth, lump-free mixes and optimizes your production process. Designed to eliminate common issues like foaming and incomplete dissolution, it provides consistent, homogenous results every time.

Ideal for challenging ingredients such as cocoa and egg white powder, the VomaBPS improves product quality and reduces waste. By minimizing air incorporation and ensuring uniform mixing, it enhances efficiency and reliability in your production.

Whether you’re making marshmallow bases or chewy candy, the VomaBPS delivers precision and consistency, meeting the high standards your products demand.

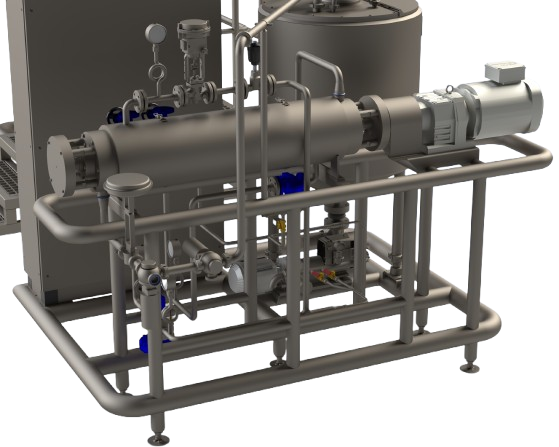

Other machines

The VomaBPS is Vomatec’s advanced high-shear mixing solution, designed to efficiently incorporate powders such as gelatin, pectin, cocoa powder, and milk powder into your production process.

This state-of-the-art mixer tackles common challenges like clumping, air incorporation, and incomplete mixing, ensuring a lump-free, homogenous result every time. Ideal for the confectionery industry, the VomaBPS ensures consistent, high-quality results for applications like marshmallow bases, chewy candy, and aerated masses.

By using advanced high-shear mixing technology, the VomaBPS eliminates air entrapment and optimizes ingredient blending, seamlessly mixing both dry and wet ingredients. This results in smoother, more efficient production, with minimal downtime and maintenance.

With its robust design and low-maintenance features, the VomaBPS enhances production efficiency, making it an ideal choice for large-scale operations. Whether integrating into existing systems or developing new processes, the VomaBPS ensures improved consistency, reduced waste, and superior product quality.

The VomaBPS provides reliable, efficient performance for manufacturers looking to solve mixing problems and achieve better results in their production processes. Contact Vomatec to learn more about how the VomaBPS can optimize your operations and improve your product consistency.