Weighing & Mixing

Specials

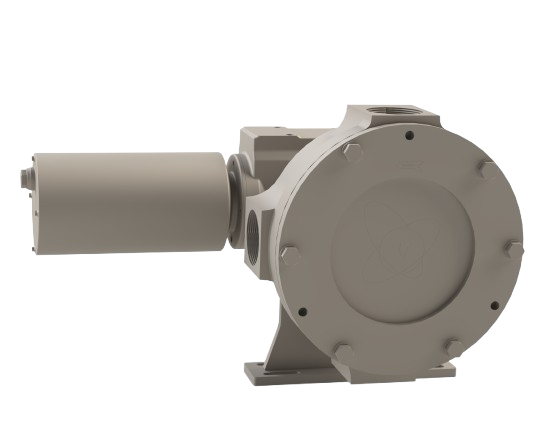

VomaBPS

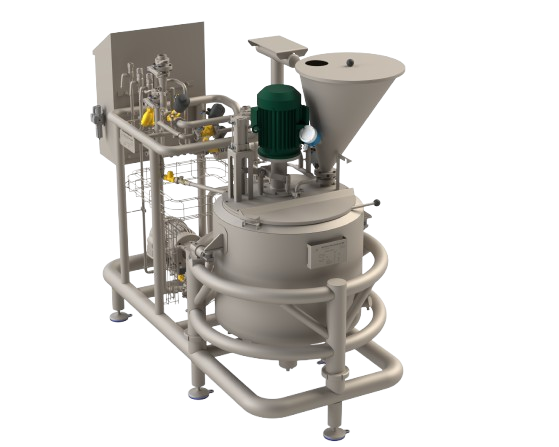

VomaMIX

Weighing & Mixing:

Precision for Consistent Quality

In confectionery production, weighing and mixing are critical process steps that directly influence the quality, texture, and consistency of the final product. Whether preparing a base syrup, integrating acids and active ingredients, or managing complex multi-phase formulations, precision at this stage lays the foundation for a stable, repeatable outcome.

Manual methods often introduce variability, especially when handling sensitive or reactive materials. Automated systems enable accurate dosing and reliable mixing of liquids and powders, reducing errors, improving efficiency, and supporting high product standards across every batch.

Core Benefits

- Accuracy: Precise dosing ensures stable formulations and consistent product quality.

- Process Efficiency: Automated workflows shorten cycle times, reduce manual input, and minimize waste.

- Material Versatility: Designed to handle a wide range of ingredient types, including shear-sensitive powders, viscous liquids, and challenging blends.

Built Around Your Process

Vomatec designs weighing and mixing systems that are modular, hygienic, and built to integrate seamlessly into your confectionery line. From pilot plants to high-output operations, our solutions offer the reliability and flexibility required for modern production environments. Each system is engineered to optimize your process flow with clean-ability, control, and consistency at its core.