Color, Flavor & Acid

Specials

VomaDOS

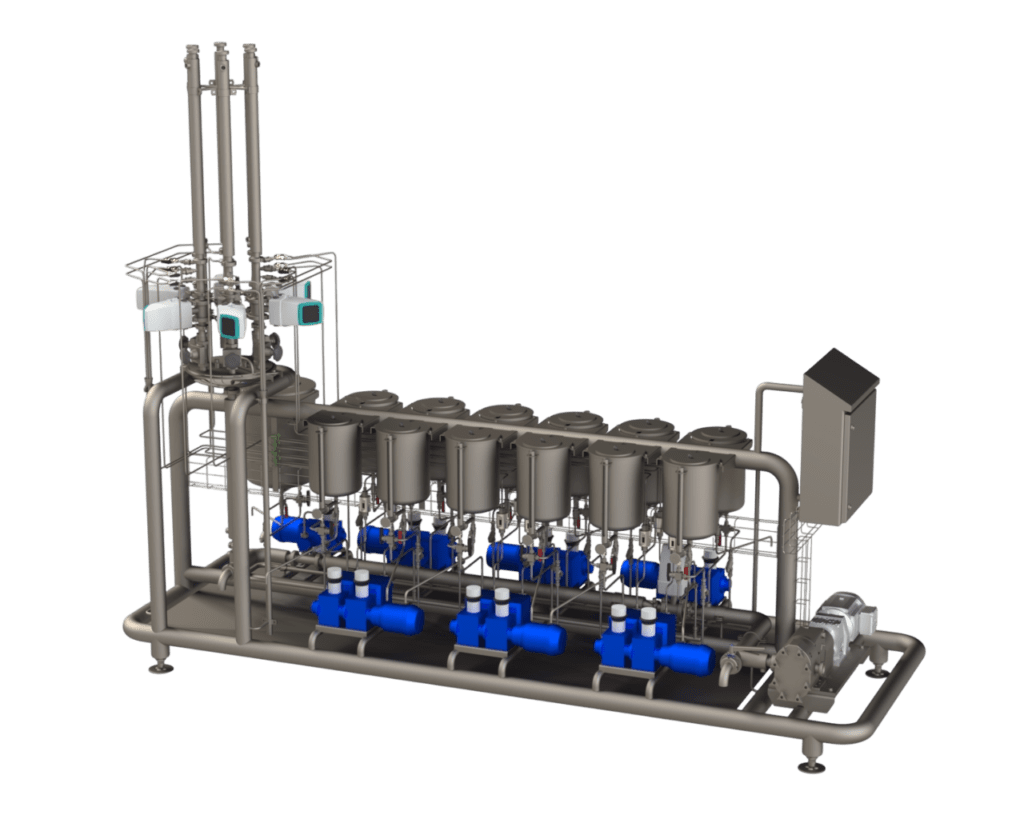

CFA Systems:

Inline Precision for Distinctive Products

In the world of confectionery production, the precise dosing of color, flavor, and acid is crucial for consistent product quality. Traditionally, artisans added these ingredients by hand, carefully balancing taste, appearance, and texture.

With the evolution of automated dosing systems, this process became faster, more precise, and scalable. Vomatec’s VomaDOS Color, Flavor & Acid (CFA) system has redefined this step, ensuring optimal dosing—whether for simple, single-color jellies or intricate, multi-flavored confections.

Core benefits

- Unmatched Consistency: Advanced dosing ensures every batch meets your exact specifications, from vibrant colors to balanced acidity.

- Precise Control: Accurate flow rates and weighing systems guarantee repeatable results, reducing errors and product deviations.

- Efficient Process: Inline dosing reduces additive waste, shortens processing times, and increases production efficiency.

Engineered for Precision and Flexibility

The VomaDOS Inline Mixer is ideal for direct injection of color, flavor, and acid additives into the product stream. Using static mixers, this system ensures a homogeneous distribution of additives, resulting in a consistent and high-quality end product. The inline configuration minimizes product loss and enhances production efficiency.

VomaDOS Loss-in-Weight System

For applications requiring extremely accurate dosing, the VomaDOS Loss-in-Weight system offers a gravimetric approach. By continuously measuring the weight loss of additives, this system ensures a constant and precise dosage, making it essential for processes where exact quantities are critical.

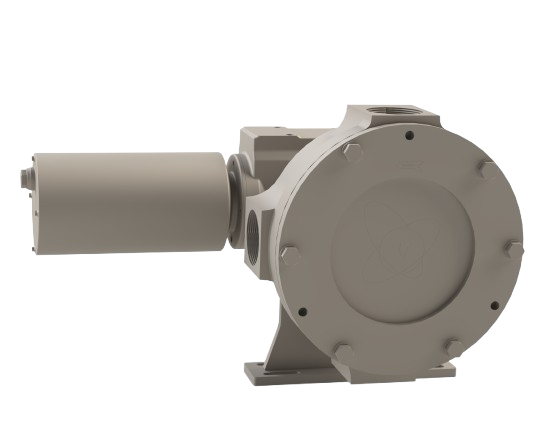

VomaDOS with Pressurized Air and Tanks

The VomaDOS system with pressurized air and tanks is designed for scenarios where additives need to be injected under pressure. This system uses compressed air to maintain a steady and controlled flow of color, flavor, and acid additives, even for high-viscosity liquids or in demanding production environments.