Advanced direct steam injection cooking

Direct

Precise

Energy

Frequently Asked Questions

Feel free to contact us.

Precision and speed in cooking

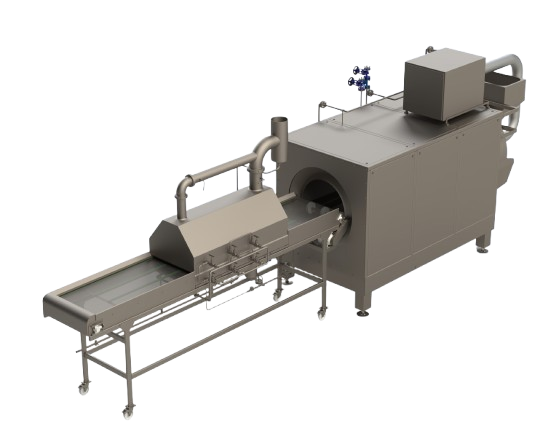

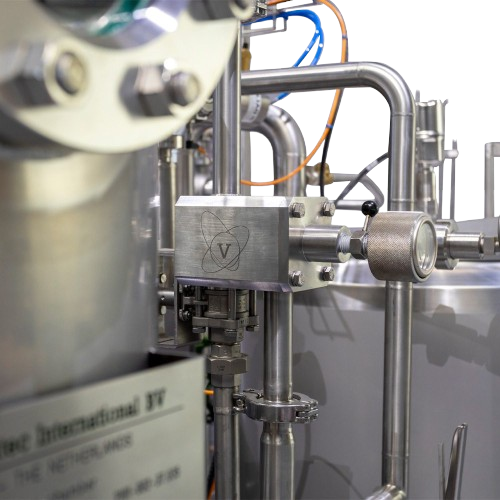

The VomaJET by Vomatec combines cutting-edge technology with robust engineering to revolutionize cooking processes in the confectionery industry. Its direct steam injection system offers rapid and uniform heating, ensuring minimal product degradation and maximizing efficiency.

Capacities ranging from 50 to 5000 kg/h make the VomaJET suitable for a wide range of production needs, from pilot plants to high-capacity production lines. Precise temperature control prevents scorching, preserving the flavor, texture, and color of your product. This is particularly important for delicate recipes like jellies and sugar syrups, where consistency is key.

The VomaJET is not only about performance but also about ease of use. Its hygienic design ensures quick cleaning and low maintenance, while its robust construction guarantees long-term reliability. The system integrates seamlessly into existing production lines or operates as a stand-alone unit, offering unmatched flexibility for modern manufacturers.

Whether you’re scaling production or optimizing an established line, the VomaJET provides the tools to enhance your efficiency, reduce waste, and improve overall product quality.

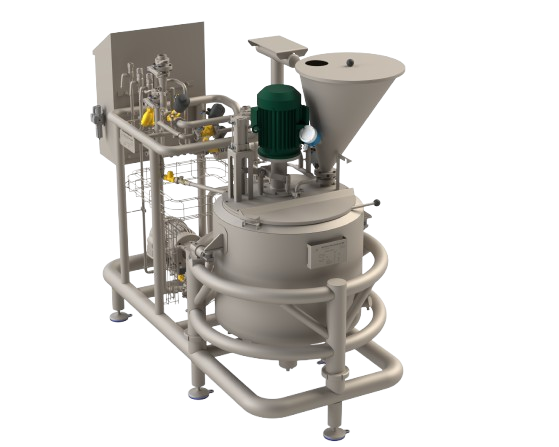

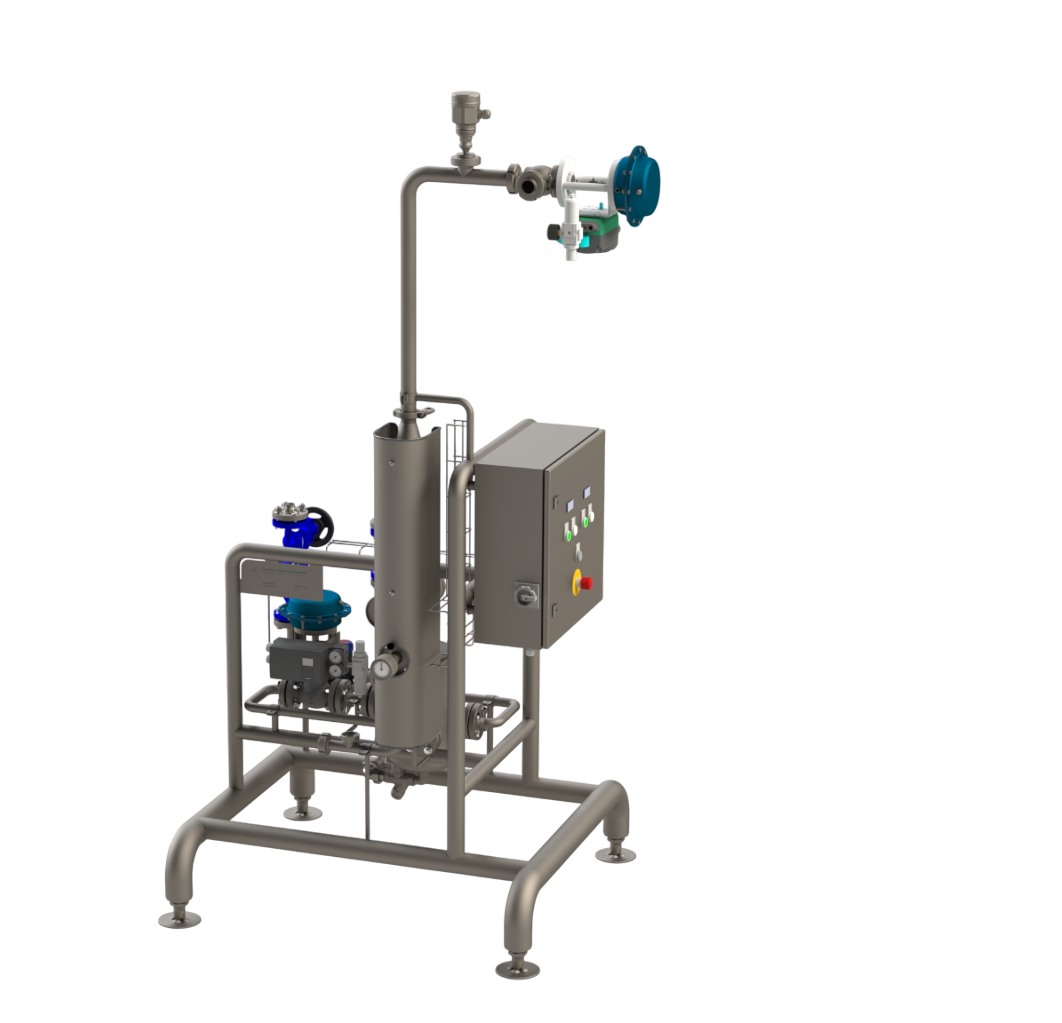

Other machines

The VomaJET delivers fast and accurate cooking using direct steam injection. This method heats sugar-based masses like jellies and syrups evenly and efficiently, without scorching or overprocessing.

Thanks to its precise temperature control and hygienic stainless-steel design, the VomaJET protects your product’s texture, color, and flavor, even in delicate formulations. It integrates seamlessly into existing production lines or runs as a stand-alone unit, minimizing cleaning time and maximizing uptime.

Built for demanding confectionery processes, the VomaJET helps you cook faster, reduce waste, and produce consistent results every time.