Nougat machine

At Vomatec, we build tailor-made systems for every stage of candy production – from weighing, mixing and cooking to forming, cooling and finishing. Each machine is designed around your product and process, whether you need a single unit or a full line. Scalable, easy to use, and built to last. With over 40 years of hands-on experience, we help you stay flexible, consistent and in control.

Specials

Need a partner for custom-built confectionery machines? V...

Cooling tables

The Vomatec Cooling Table offers precise, contact-based c...

Glucose tank

The Vomatec Glucose Tank ensures stable, crystal-free sto...

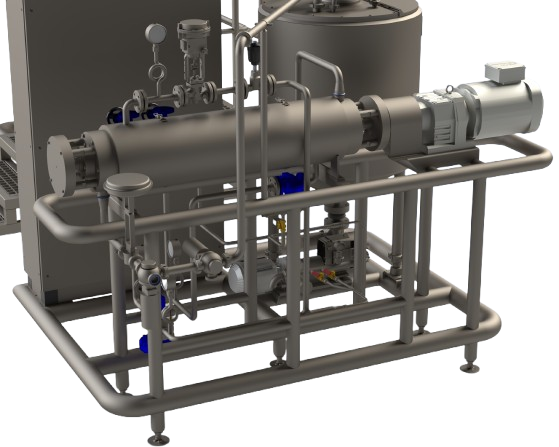

VomaTHERM

The VomaTHERM is a batch cooker with natural thermosyphon...

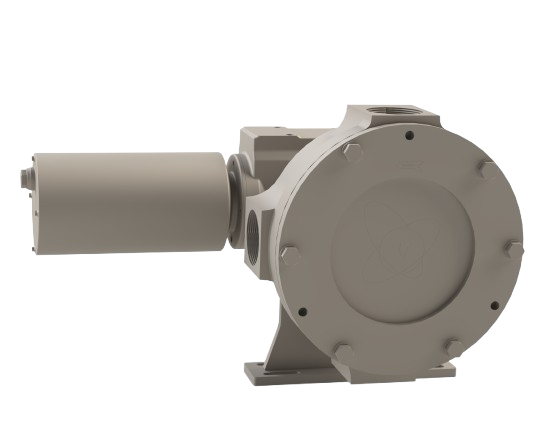

VomaRC

A continuous scraped-surface cooker for precise heat cont...

VomaWHISK

The VomaWHISK is Vomatec’s advanced whipping system des...

VomaMIX

The VomaMIX is an advanced mixing and weighing system des...

nougat candy production

Nougat production with Vomatec:

Airy, creamy, and full of flavor

Nougat is a timeless confectionery classic, loved for its airy, soft texture and rich, indulgent taste. Made from sugar, honey, egg whites, and nuts, nougat is a versatile treat often used in bars or as a filling in chocolates. Its signature lightness is achieved through carefully controlled aeration, where precision and temperature management are critical to achieving the perfect consistency.

Advanced solutions for nougat production

At Vomatec, we provide cutting-edge machines designed to optimize every step of the nougat-making process. From whipping and aerating ingredients to precise cooking and finishing, our equipment ensures consistency, quality, and efficiency in every batch.

Other categories

Caramel machine

Smooth caramel with perfect texture from accurate cooking parameters.

Sugar free machine

Sugar-free, same quality – demanding precision and recipe stability.

Marshmallow machine

Airy, elastic texture achieved through perfect aeration and temperature control.

Hard candy machine

Crystal-clear candy through exact cooking and controlled cooling processes.