Production kitchen

Specials

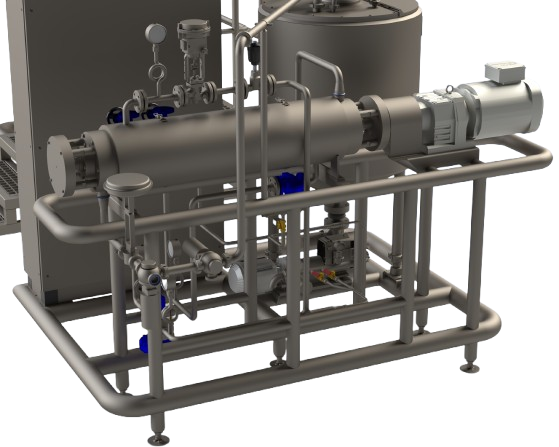

VomaCLEAN

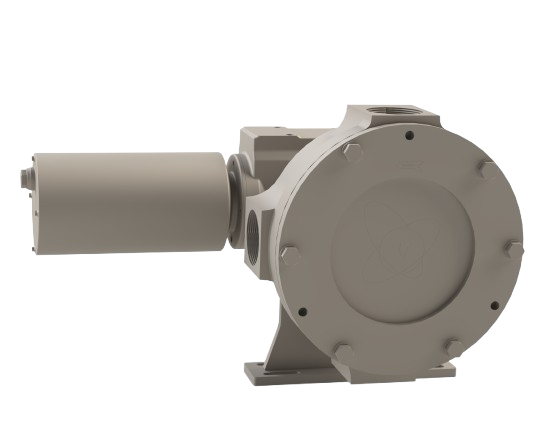

VomaFC

VomaEXTRUDE

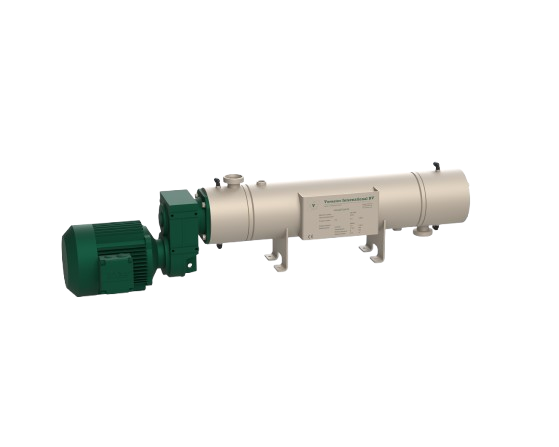

VomaTHERM

VomaJET

VomaRC

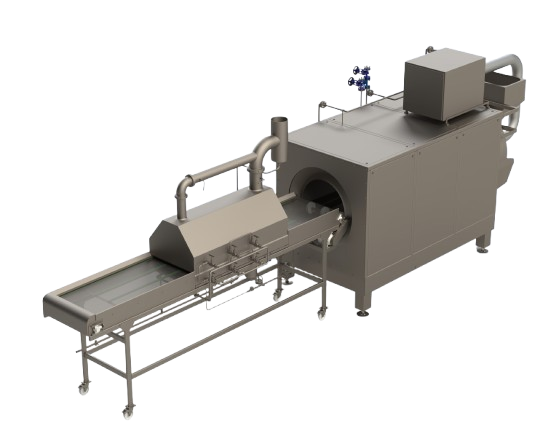

VomaCOAT

VomaSHINE

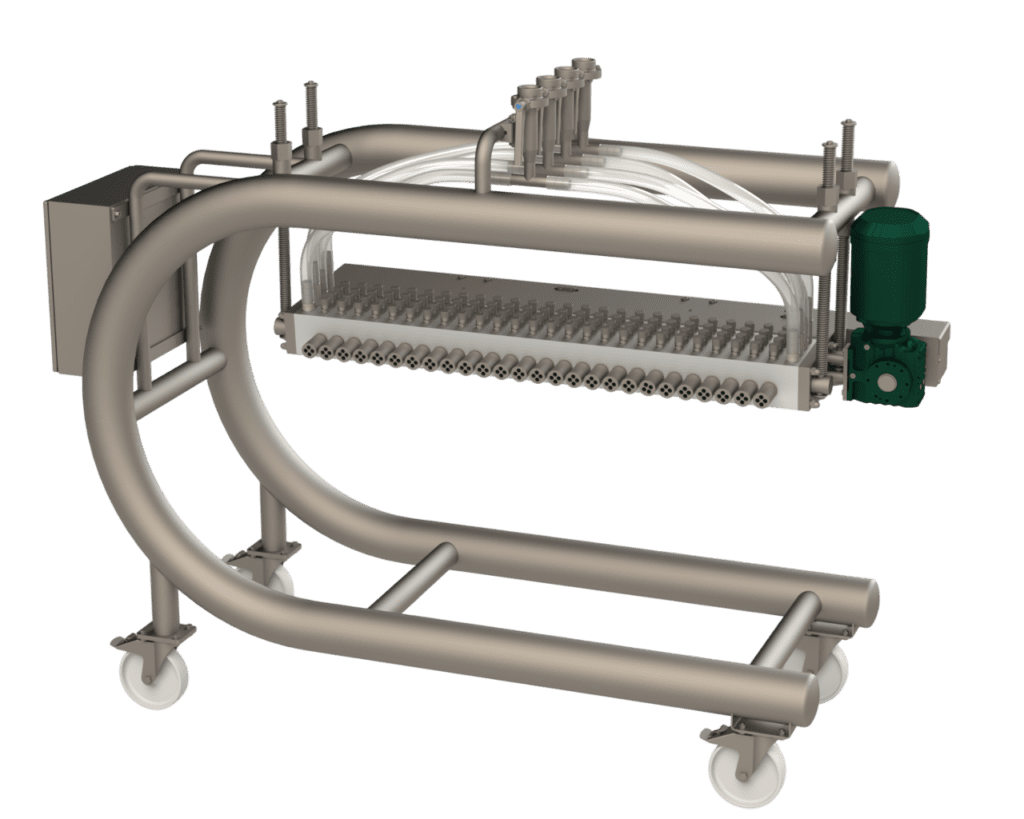

VomaWHISK

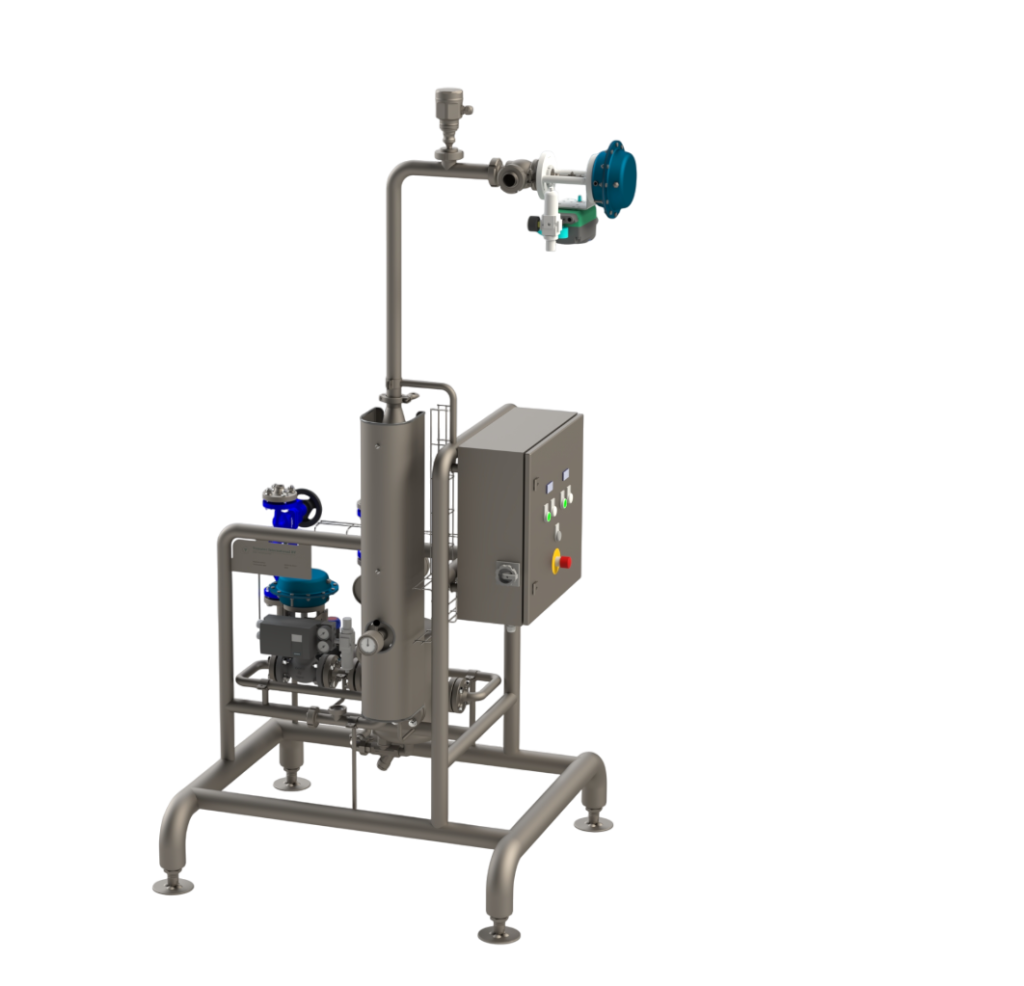

VomaCOOK

VomaTEMP

VomaTAB

VomaDOS

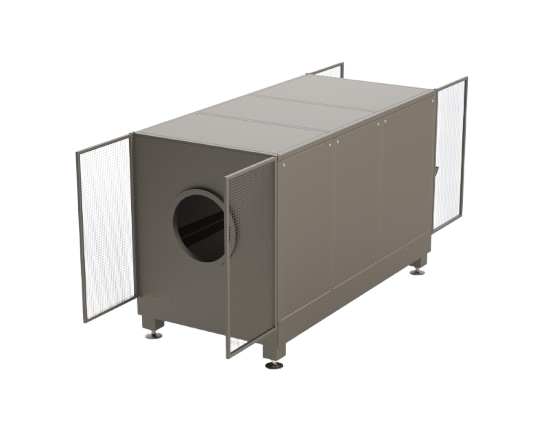

VomaBPS

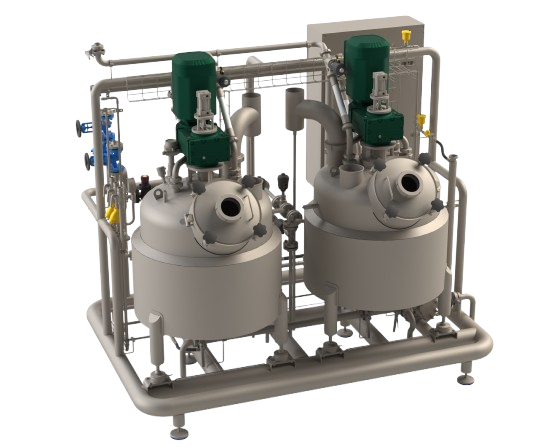

VomaMIX

VomaDISS

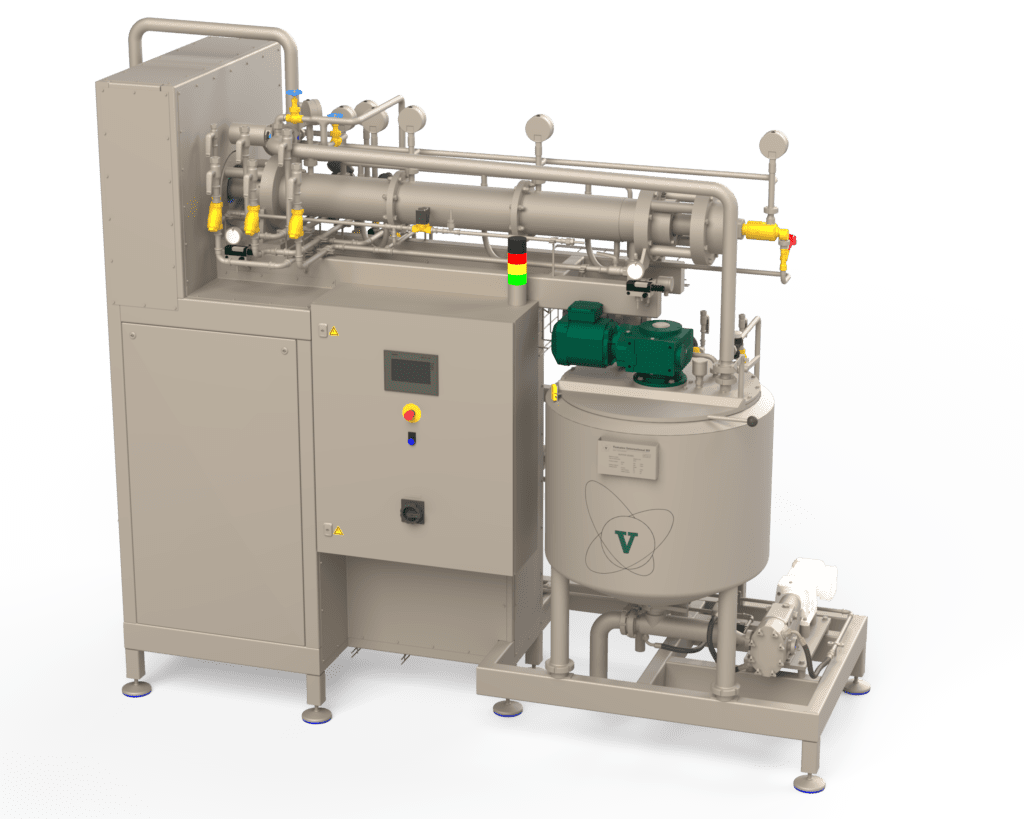

Production kitchens:

Precision for confectionery and nutraceuticals

Production kitchens are essential for high-quality manufacturing in the confectionery and nutraceutical industries. These advanced systems ensure consistent results in cooking and mixing processes, whether scaling up from pilot plants or optimizing existing lines. Designed for flexibility and efficiency, Vomatec’s production kitchens meet the demands for variety, sustainability, and cost-effectiveness with precision and reliability.

The Strength of Production Kitchens

Scalability: Designed to support seamless transitions from small to large-scale production.

Precision: Ensures accurate mixing, cooking, and processing for consistent results.

Efficiency: Reduces downtime and waste while maximizing production output.

Vomatec: Expertise in Production Kitchens

At Vomatec, we design production kitchens that combine precision engineering with innovative technology. Our solutions include:

- Custom Configuration: Tailored to meet your unique production needs.

- Energy Efficiency: Advanced designs that optimize energy consumption.

- Reliable Performance: Built for continuous operation with minimal downtime.

Vomatec’s production kitchens are more than systems—they’re your partner in delivering exceptional quality at scale.