Finishing

Specials

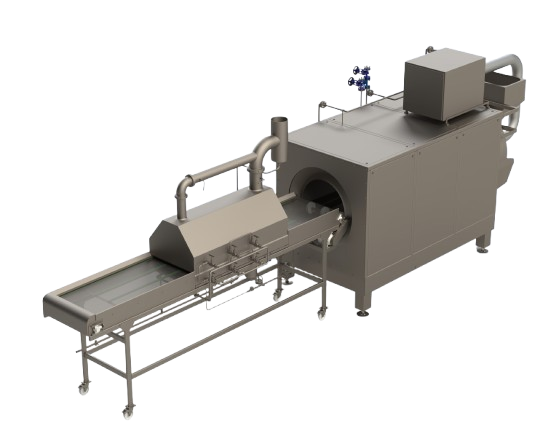

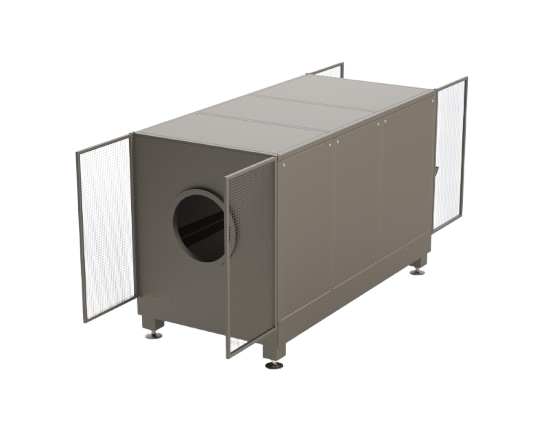

VomaCLEAN

Cooling tables

VomaEXTRUDE

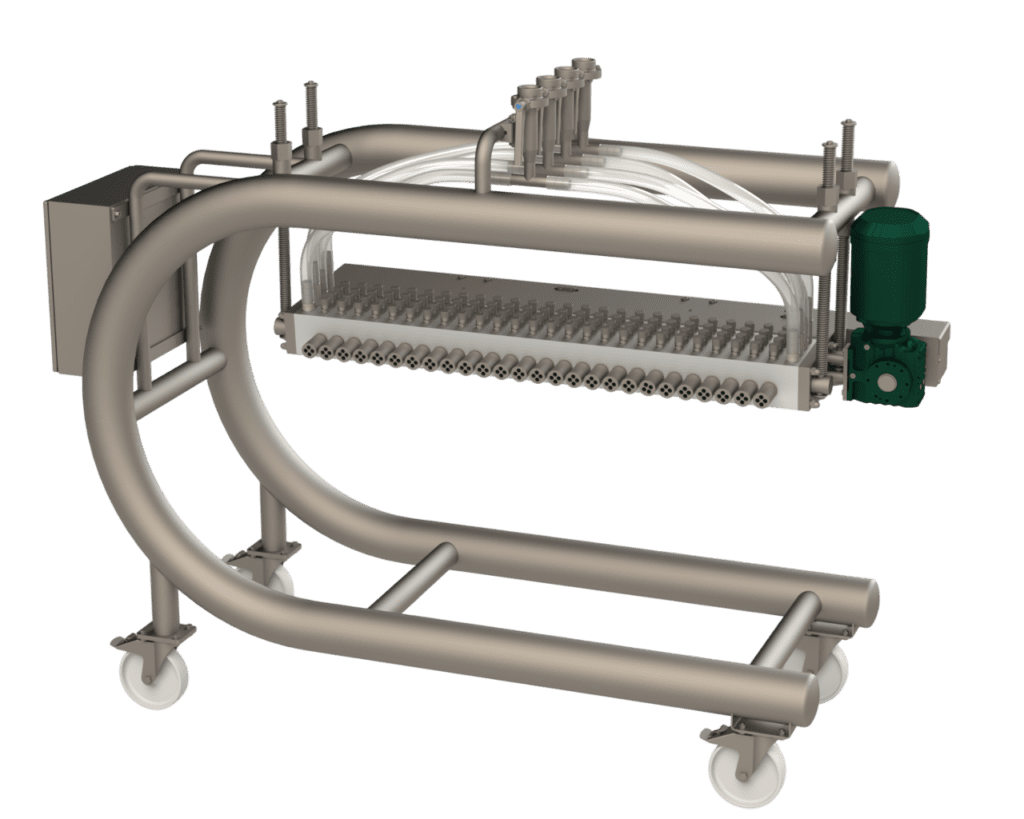

VomaCOAT

VomaSHINE

Finishing:

From Clean Surface to Finished Product

In confectionery production, finishing is the final step before packaging — and it plays a critical role in product quality, shelf life and consumer appeal. Whether cleaning off starch residue, applying a sugar or oil coating, or polishing to a smooth shine, each action must be precise and repeatable.

Manual methods are no longer sufficient for high-output production. Automated systems ensure uniform handling and controlled application, helping manufacturers deliver consistently finished products with minimal waste or rework.

s.

Core Benefits

- Cleanliness and Hygiene: Ensures products are free of excess residue, maintaining the highest standards of safety and quality.

- Protective Coating: Uniform application of sugar, oils or acids helps preserve texture, prevent drying, and support storage stability.

- Visual Appeal: Gentle polishing adds a glossy, smooth finish that enhances the product’s appearance and consumer perception.

Designed for Modern Finishing Lines

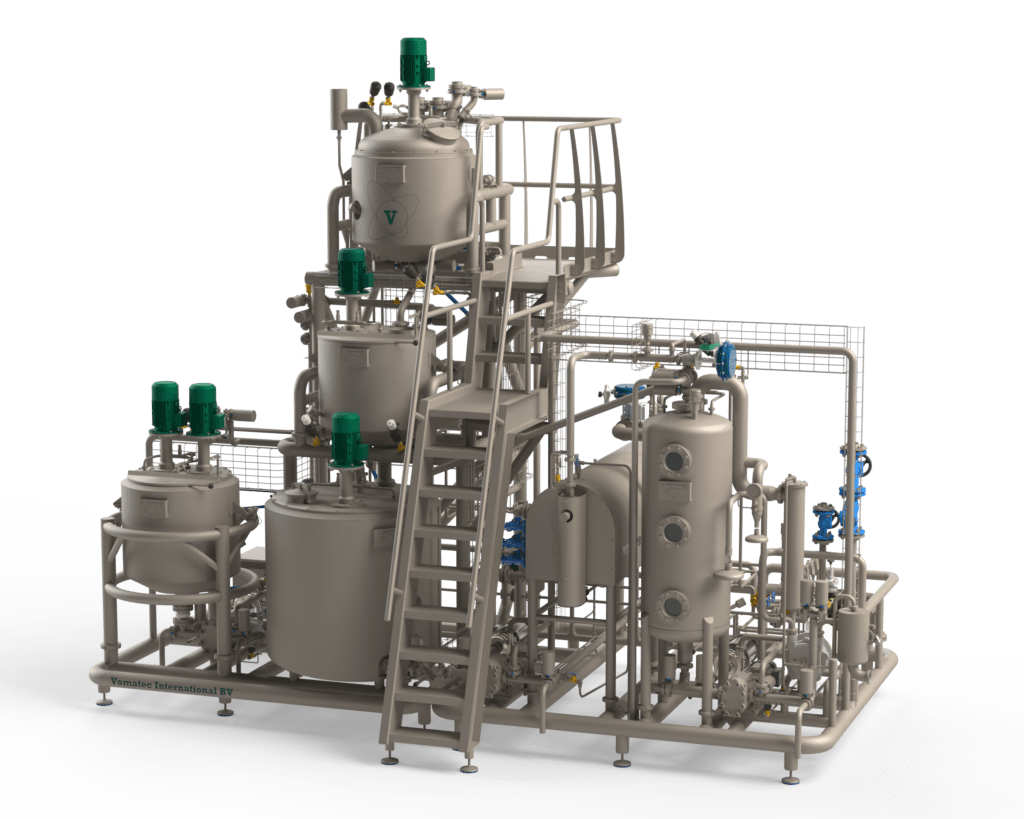

Vomatec builds some of the most refined and durable finishing systems in the industry — engineered for hygiene, control and product integrity. Each installation is designed with high-grade stainless steel, modular construction, and minimal product stress in mind.

From starch removal to coating and polishing, every step is executed with precision. The result: consistent appearance, longer shelf life, and reliable downstream performance.

Whether used in pilot plants or high-output production lines, Vomatec’s finishing technology sets the standard for quality, cleanability and continuous operation.

Other categories

Batch cooking

Finishing