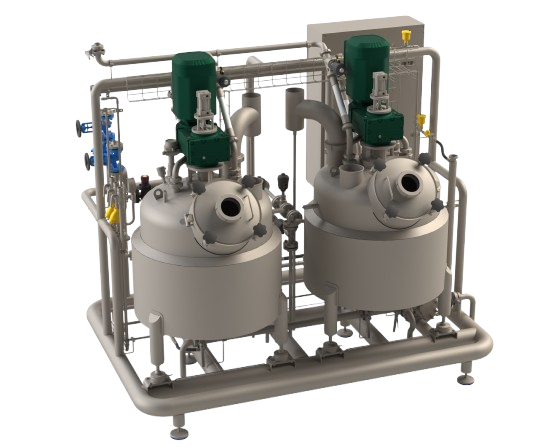

Batch cooking

Specials

VomaTHERM

VomaCOOK

Batch Cooking:

From Tradition to Modern Innovation

Batch cooking remains a cornerstone in the production of sugar-based confectionery. Whether developing caramel, nougat, or fudge, this method offers precise control over heat transfer, product consistency, and flavor development especially for sensitive recipes that demand careful processing.

While the principles remain rooted in tradition, modern batch cooking systems have evolved to improve repeatability, energy efficiency, and hygiene. Automated temperature control, indirect heat transfer, and closed systems reduce the risk of scorching or over processing, all while maintaining the quality that defines handcrafted confectionery.

Core Benefits

- Optimized Heating Profile: Even temperature distribution enhances flavor while reducing risk of burn-on or overprocessing.

- Process Stability: Accurate dosing and temperature regulation ensure consistency from batch to batch.

- Scalable Versatility: Suitable for both small test batches and large-scale production.

Engineered for Practical Excellence

Vomatec designs batch cooking systems that combine durable construction with low-maintenance operation. With no moving parts in the heat transfer zone and hygienic, easy-to-clean configurations, our systems offer long-term performance with minimal downtime. Whether you’re scaling up or fine-tuning recipes, our batch cooking technology provides the control, repeatability, and quality your process demands.